You count on automotive electrical terminals to keep your car safe and working well every day. New ways of making them and better materials help your car work better.

If you use bad connectors, your car may not work right. This can cause safety problems, break rules, and cost more money over time. As electric cars and new car systems get more common, high-precision terminals are needed for better performance.

Automotive Electrical Terminals Overview

Definition and Role

Every time you start your car, you use automotive electrical terminals. These are small metal pieces inside your car. They connect wires and cables together. This lets power move from the battery to things like the engine and lights. When you press a button or turn the key, the terminals send signals to the right places. Without these parts, your car would not work or keep you safe. Automotive electrical terminals come in many shapes and sizes. Some are flat, some are round, and some look like pins. Each kind has a special job in your car. You can find them in connectors, fuse boxes, and control modules. They hold wires tight and help electricity move easily. If a terminal stops working, you might see warning lights or lose power. Sometimes, your car may not even start.

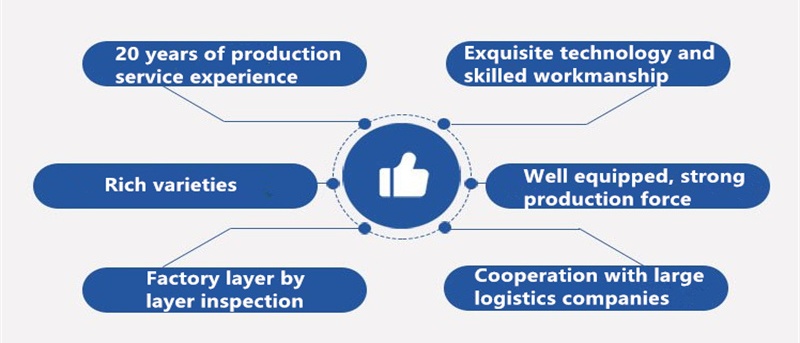

Jiaxin (Xiamen) Precise Metal Co., Ltd. is a top maker of these terminals. The company uses strong materials and new technology. This helps each terminal work well, even in tough places. Their products last a long time and keep your car’s electrical system strong.

Importance in Vehicle Systems

Automotive electrical terminals do more than just help you start your car. They are important for every part of your car’s electrical system.

Here are some reasons why they matter:

-

They keep power and signals steady so your car works right.

-

Good terminals block water and dust to protect electronics.

-

They help the engine, ignition, and fuel injectors work together.

-

Strong terminals lower the chance of breakdowns and keep you safe.

When you pick good automotive electrical terminals, your car runs better and lasts longer. Their importance grows as cars get more advanced. You need strong connections for things like sensors, safety systems, and electric motors. That is why many experts choose Jiaxin for their cars.

Key Features ofHigh-Quality Terminal Connectors

Material Selection and Finishes

When you look at good terminal connectors, you see the materials and finishes first. These connectors use strong metals like Be-Cu, CuSn4, CuSn6, SUS301, and SUS304. Each metal helps the connector last longer and work better in cars. The right finish keeps the connector safe from rust and damage. You can find finishes like tin, gold, silver, and nickel. These finishes help the connector handle heat, water, and wear.

Here is a table that shows some common materials and finishes, along with their advantages:

|

Testing Method

|

Purpose

|

Key Features

|

|

Continuity Testing

|

Checks for complete electrical paths

|

Finds open or short circuits

|

|

High-Voltage (Hi-Pot) Testing

|

Tests insulation under stress

|

Needed for electric vehicles

|

|

Pull-Force Testing

|

Checks strength of joints

|

Makes sure crimps stay secure

|

|

Crimp Cross-Section Analysis

|

Looks at crimp quality under a microscope

|

Finds voids or weak spots

|

|

Environmental Stress Testing

|

Tests in heat, cold, and vibration

|

Includes salt, humidity, and vibration tests

|

|

Visual and Label Inspection

|

Checks appearance and labels

|

Done by trained inspectors

|

|

Functional Testing

|

Checks system performance

|

Includes live system checks

|

You can also find different thicknesses for each type. Flat connectors are usually between 0.3 and 0.5 mm thick. Cylindrical ones are often 0.3 to 0.4 mm thick. These features help connectors fit many uses in cars.

Precision Manufacturing

You want terminal connectors to work every time. Special machines build these connectors with care. Automated lines put each part in the right place. Robots handle small wires and parts with high accuracy. Real-time checks look for problems as connectors are made. Smart tools test each connector to make sure it meets strict rules.

-

Automated machines help lower mistakes and keep quality high.

-

Robots make sure each wire and part fits just right.

-

Quality checks happen at every step of making connectors.

Manufacturers use lean methods and Six Sigma to keep things running smoothly and cut down on waste. They use digital calipers, automated checks, and special tools to look at every connector. These steps help you get connectors you can trust every time.

Customization and Validation

Every car is different.Good terminal connectorscan be made to fit your needs. You can pick the size, shape, and finish that works for your project. This makes putting cars together easier and helps stop mistakes. Many companies work with you from design to making the connectors. They help you if you are an OEM or a Tier 1 supplier. To make sure each connector works well, companies use many tests. Here is a table of common tests and what they do:

|

Testing Method

|

Purpose

|

Key Features

|

|

Continuity Testing

|

Checks for complete electrical paths

|

Finds open or short circuits

|

|

High-Voltage (Hi-Pot) Testing

|

Tests insulation under stress

|

Needed for electric vehicles

|

|

Pull-Force Testing

|

Checks strength of joints

|

Makes sure crimps stay secure

|

|

Crimp Cross-Section Analysis

|

Looks at crimp quality under a microscope

|

Finds voids or weak spots

|

|

Environmental Stress Testing

|

Tests in heat, cold, and vibration

|

Includes salt, humidity, and vibration tests

|

|

Visual and Label Inspection

|

Checks appearance and labels

|

Done by trained inspectors

|

|

Functional Testing

|

Checks system performance

|

Includes live system checks

|

These features help you trust that your connectors will work in any condition.

Connectivity and Reliability Benefits

Consistent Performance

You want your car to start every time you try. High-precision terminalshelp make this happen. These terminals give strong and steady connections. Power and signals move easily through your car’s systems. They use metals that carry electricity well. The way they are made is very careful. This helps your car work the same, even in heat, cold, or when it shakes.

High-precision terminals are made by following strict rules. They meet standards like IPC620. They also use a quality system called IATF 16949. Every terminal gets checked by machines. Each one is tested to make sure it works right. This helps stop problems before they reach your car.

Here is a table that shows how these rules and checks help:

|

Evidence Description

|

Details

|

|

Manufacturing Standards

|

Made by following IPC620 rules for each part.

|

|

Quality Management

|

Uses IATF 16949 system for better processes.

|

|

Quality Assurance

|

Machines check and test every terminal for mistakes.

|

|

Production Quality

|

Meets high standards for important car parts.

|

You can trust these terminals to keep your car’s wires working. They help your car handle bumpy roads and bad weather. This kind of reliability is needed for today’s cars.

Reduced Failure Rates

Using high-precision terminals means fewer wiring problems. These terminals help your car last longer. You will need fewer repairs. They keep the wiring harness safe and strong. This saves you time and money on fixing your car.

The right terminals also keep your car safe from things like short circuits or fires. They make sure every connection stays tight. This keeps you and your passengers safe.

Here is a table that explains the main benefits:

|

Benefit

|

Description

|

|

Improve automotive performance

|

Makes sure power and signals move well.

|

|

Reduce failure rate

|

Helps wires last longer and lowers repair costs.

|

|

Enhance safety

|

Stops dangers like short circuits and fires.

|

These terminals are tested before they go in your car. Companies check for things like if the wires connect right and if the insulation is good. They see if the terminals can handle high voltage and shaking. They also test if they work in hot or cold weather. These tests follow rules like AEC-Q103, ISO 16750, and ISO 26262. This means you get safe and reliable parts.

Validation testing includes:

|

Testing Type

|

Purpose

|

Importance

|

|

Continuity Testing

|

Checks if wires connect all the way.

|

Finds broken wires or wrong connections that could cause problems.

|

|

Insulation Resistance Testing

|

Makes sure wires are covered well.

|

Stops leaks and short circuits, which is very important for high voltage.

|

|

High-Potential (Hipot) Testing

|

Checks if insulation can handle high voltage.

|

Keeps the system safe if there is a sudden voltage spike.

|

|

Contact Resistance Testing

|

Measures how well connections let power flow.

|

Makes sure signals and power move without getting too hot or losing strength.

|

|

Mechanical Testing: Pull Force and Vibration

|

Checks if terminals stay strong when pulled or shaken.

|

Makes sure wires do not come loose in tough conditions.

|

|

Environmental Testing

|

Tests if terminals work in extreme weather.

|

Needed for cars that face rain, heat, or cold.

|

|

Color Difference and Wire Position Analysis

|

Checks wire colors and where wires go.

|

Stops mistakes that could cause problems or safety issues.

|

High-precision terminals do more than just join wires. They help your car stay safe and work well. With good connections, you can feel safe every time you drive.

Safety and Importance in Vehicle Systems

Preventing Electrical Faults

You want your car to be safe every time you drive. High-precision terminals help stop many electrical problems. These small parts give safe and strong connections. Electricity can move without trouble. This means power goes to every part of your car. Good conductivity lets energy move easily. This helps your car work its best. Strong materials make these terminals last longer. They can handle wear and tear better.

High-precision terminals are made to fight rust, heat, and shaking. This keeps them working in hard conditions. Using these terminals helps stop overheating and damage to important car parts.

Some common electrical problems you can avoid are:

-

Loose connections that make lights flicker or sensors not work

-

Corrosion and oxidation that block electricity and lower performance

-

Bad crimping that causes weak connections and system failures

Supporting Critical Systems

You count on many safety systems in your car. These includeadvanced driver assistance systems and battery management. High-precision terminals are very important for these systems. They help sensors, cameras, and controllers work together. For example, these terminals help ADAS sensors like radar and lidar stay in place. This gives you correct readings. The micro-stamping process makes sure signals move without mistakes. This is very important for your safety.

Here is how high-precision terminals help battery management systems:

|

Functionality

|

Description

|

|

Accurate Monitoring

|

Lets you check cell voltages and temperatures for safety and efficiency.

|

|

Cell Balancing

|

Keeps battery cells working well and stops overheating.

|

|

Pack Monitoring

|

Watches high voltage, current, and temperature to keep battery packs safe.

|

Real-world results show these terminals really help. For example, stability control systems with high-precision terminals can cut single-car crashes by 52.6%. Newer systems have also lowered serious injuries by up to 72%.

You can trust high-precision terminals to keep your car’s systems safe and working right.

Integration in Modern Vehicles

Automotive wire connectors are found all over modern cars. They help connect wires for power, signals, and data. Battery management systems use them to keep batteries safe and working. Motor controllers need them so cars can move smoothly. Sensors use these connectors to send information to the car’s computer. Powertrain systems use them to control the engine and transmission. Chassis systems need them for brakes, steering, and suspension.

Here is a table that shows whereautomotive wire connectorsare used in cars:

|

Application Area

|

Purpose

|

|

Battery Management

|

Watches and balances battery cells

|

|

Motor Controllers

|

Runs electric motors

|

|

Sensors

|

Sends data for safety and performance

|

|

Powertrain

|

Connects engine and transmission systems

|

|

Chassis

|

Links brakes, steering, and suspension

|

These connectors help keep your car safe and working well. You need the right connector for each job. Each one has a special shape and size for its use.

Versatility Across Systems

Automotive wire connectors work in many different car systems. There are many types, like pin connectors, blade connectors, and ring terminals. Each type is best for certain jobs. Pin connectors are good for sensors. Blade connectors work well for power circuits.

Connectors must handle heat, cold, and shaking. Jiaxin gives you help to pick the right connector for your needs. You can get help with design, testing, and making the connectors. This makes it easy to find the best one for your project.

You can trust Jiaxin to give you connectors for many cars and systems. Their products work with new technology and changing needs. You get strong and steady performance in every part of your car.

FAQ

What makes high-precisionterminals important for vehicles?

High-precision terminals help keep your car safe. They make sure power and signals move easily. These terminals also protect against heat, shaking, and rust.

How do I choose the right terminal for my project?

Check the size, shape, and finish of each terminal. Think about where you will use it in your car. If you are not sure, ask your supplier for help.

Can high-precision terminals improve safety features?

Yes, they can help safety systems work better. These terminals let sensors and controllers work together. This helps things like airbags and ADAS work right.

Where are automotive electrical terminals used?

You can find these terminals in many car parts. They connect wires in battery management, sensors, powertrain, and chassis. Every modern car needs strong and steady connections.