Intelligent vision Counting Systems: Precision for Modern Warehousing

In today's Industry 4.0 landscape, warehouse efficiency and accuracy are crucial to competitive supply chain performance. Businesses handling bulk granular materials—such as fasteners, pharmaceuticals, seeds, electronic components, and jewelry accessories—often face inefficiencies and inaccuracies during counting processes. Manual methods are slow, prone to errors, and struggle with mixed batches or irregularly shaped items.

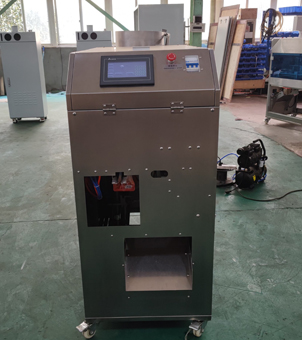

Hefei The One Electronic Technology Co., Ltd. specializes in advanced warehouse vision counting machine designed to overcome these challenges. Our machines enhance workflow accuracy, reduce operational costs, and support seamless digital integration—making them ideal for modern warehouses aiming for full automation.

The Limitations of Manual Counting & Our Automated Approach

Common Issues with Traditional Methods

Time-consuming counting reduces throughput in receiving, sorting, and shipping.

Human errors lead to inaccurate inventories, financial discrepancies, and customer disputes.

High reliance on labor increases operational costs and limits scalability.

Manual data entry creates delays, inaccuracies, and poor traceability.

How Our vision Counting System Works

Equipped with high-resolution industrial cameras and proprietary AI-based vision algorithms, our system instantly recognizes, analyzes, and counts particles—even when overlapping or irregularly shaped.

Unmatched Speed and Accuracy: Count thousands of items per minute with near-perfect accuracy.

Wide Material Compatibility: Works with screws, capsules, seeds, electronic parts, beads, and more.

Real-Time System Integration: Compatible with WMS, ERP, and other warehouse management platforms for automated data synchronization.

Key Use Cases in Warehouse Operations

Incoming Goods Inspection

Rapidly verify quantities during receiving—whether performing full checks or random sampling—to ensure order accuracy and reduce offloading time.

Inventory Sorting and Cycle Counting

Integrate into packing lines for automated batch splitting and efficient stocktaking. Ideal for kitting and custom order fulfillment.

Outbound Quality Control

Recheck quantities before shipping to prevent order errors, reduce returns, and strengthen customer trust.

Fully Automated Packaging and Labeling

Select advanced models that combine counting, packaging, and labeling into one seamless operation—printing labels with item name, quantity, batch number, and date in compliance with international traceability standards.

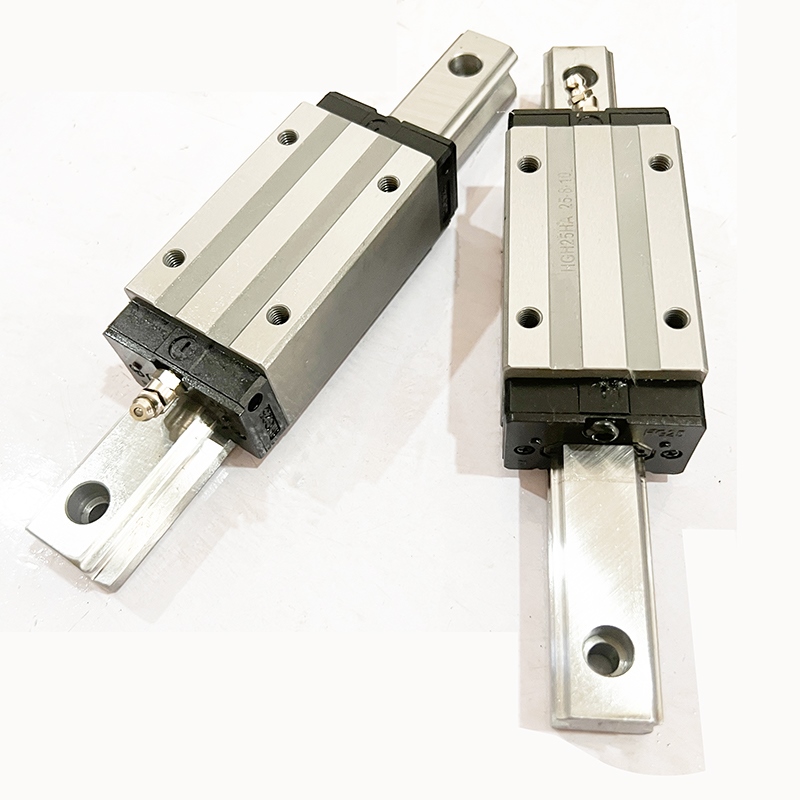

Engineered for Performance and Reliability

We independent developmed machine vision algorithms ensure robust performance across diverse industrial environments. Our systems are already trusted across industries including pharmaceuticals, agriculture, electronics, hardware, and retail logistics.

Designed to support lean management and Industry 4.0 readiness, our vision counters help businesses minimize waste, maximize efficiency, and transition toward fully automated warehouse operations.

Upgrade to a smarter, error-free warehouse with our vision counting systems.