Air cooled screw chillers are a good way to fix cooling problems in factories. These systems work well and can be used in many ways. Many factories pick air cooled chiller units because they are simple to set up. They do not need cooling towers or extra water systems. People often switch to air cooled chillers to save water and need less maintenance. They also help cool bigger areas. These chillers help with energy use, space, and meeting environmental goals.

Key Takeaways

-

Air cooled screw chillers are easy to set up. They do not use much water. They are simple to take care of. This makes them great for many factories.

-

These chillers have screw compressors that work well. They use smart controls to save energy. They help keep the temperature steady.

-

Picking the right chiller size saves money. A modular design helps meet factory needs as they change.

-

Doing regular maintenance is important. Cleaning coils and checking oil keeps chillers working well. This also helps them last longer.

-

Air cooled screw chillers can be changed to fit different needs. They have strong safety features. This makes them good for many industries and places.

Air Cooled Screw Chiller Overview

How It Works

Air cooled screw chillers use a closed refrigeration cycle to take away heat from factory processes. There are four main steps in the system: compression, condensation, expansion, and evaporation. The screw compressor has two spiral rotors that spin together. This design helps the refrigerant get squeezed gently and quietly. Next, the refrigerant goes to the condenser. Fans blow air over copper tubes and aluminum fins. This step lets heat escape into the air. The refrigerant cools down and passes through an expansion valve. This valve lowers the pressure. In the evaporator, the refrigerant takes heat from the process water. This cools the water before the cycle starts again. The OUMAL 30 Ton Air Cooled Screw Chiller uses this process to give steady and dependable cooling for many factories.

-

The system has these parts:

-

Compressor

-

Condenser

-

Evaporator

-

Control system

-

These parts work together to make a high-efficiency solution for cooling in factories.

Key Features

|

Feature |

Air-Cooled Screw Chiller |

Water-Cooled Chiller |

|---|---|---|

|

Cooling Medium |

Uses air around it |

Uses water |

|

Cooling Equipment |

Fans help get rid of heat |

Needs cooling towers |

|

Water Consumption |

Uses little water |

Uses a lot of water |

|

Installation |

Can go outside, easy to set up |

Goes inside, harder to set up |

|

Maintenance |

Medium, no cooling tower needed |

More work, needs water treatment |

|

Efficiency |

Works well in many places |

Better for very big jobs |

The OUMAL air cooled screw chiller has a semi-hermetic screw compressor, a copper condenser, and a shell-and-tube evaporator. It uses a Siemens PLC control system with a touch screen, so it is easy to use. The chiller uses R-407C, which is a refrigerant that is better for the environment. It meets strict rules for the environment. Special safety features help keep the cooling system working well.

Main Applications

Air-cooled chillers are used in many industries that need reliable chillers for cooling. Some common uses are:

-

Plastics factories use them to control mold temperature

-

Electronics factories use them to keep things stable

-

Chemical plants use them to stay safe

-

Food and drink factories use them to cool things fast

-

Medical and drug companies use them for clean rooms

-

Car and printing factories use them to protect machines

These chillers also work well where there is not much water. The OUMAL air cooled chiller can be used with other cooling systems. This makes it a good choice for many factory cooling needs.

System Sizing

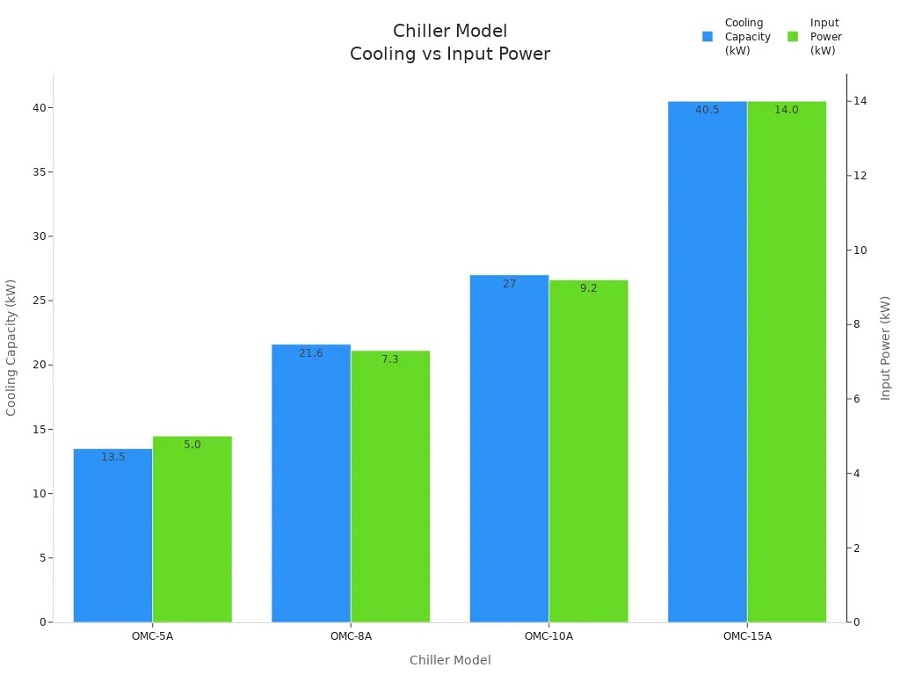

Flexible Capacity

Factories need chillers that can handle many jobs. Sometimes, factories change their machines or add new ones. A modular design lets chillers fit different needs. The OUMAL air cooled screw chiller has a modular design. Users can pick the size and features they want. They do not have to buy a chiller that is too big or too small. This helps save both money and energy.

Capacity control is also very important. The OUMAL process chiller can change its cooling power in steps from 25% to 100%. This means it can match how much cooling is needed at any time. If the factory needs less cooling, the chiller uses less energy. If more cooling is needed, the chiller gives more power. This makes the system work well and stay reliable.

-

Step modulation for capacity control helps:

-

Use less energy when cooling needs are low

-

Make the compressor last longer

-

Keep the temperature steady for sensitive jobs

-

Some chillers use variable-speed drives. These drives let the compressor and fans change speed smoothly. This gives even better control and saves more energy. Using the right controls can lower electricity use by over 12% in some cases. The OUMAL process chiller uses smart controls to work its best in all situations.

Sizing Tips

Getting the right size chiller is very important. If the chiller is too small, it cannot cool enough. If it is too big, it wastes energy and costs more to run. Here are the main steps to size an air cooled screw chiller:

-

Find out the total heat load. Add up heat from machines, people, and outside. Think about the temperature and humidity you want.

-

Look at the type of factory and how many hours it works each day. Check how much heat the equipment makes.

-

Use this formula: Capacity (Tons) = Total Heat Load (BTUs) / 12,000. This tells you the size you need.

-

Pick the right chiller type for your job. Screw chillers are best for big factories and tough jobs.

-

Plan for the future. Think about adding new machines or working longer hours. Do not just look at cost. Efficiency and how well it works over time are most important.

Tip: Always talk to a chiller expert before you decide. OUMAL can make custom chillers for special needs. Their team can help with sizing and design so the chiller fits your job.

Industrial chillers like the OUMAL model can be made to fit each project. This makes sure the system works well and saves energy. Good planning and the right features help factories get the best from their cooling system.

Energy Efficiency

Compressor Technology

Industrial chillers use special screw compressor technology to save energy. The screw compressor has two rotors that spin together. This design makes the compressor quiet and smooth. Many air-cooled chillers use this compressor because it saves power. It also works well in big factories. The compressor can change its speed and power. This helps match how much cooling the plant needs. So, the chiller does not waste energy when less cooling is needed.

-

Screw compressors help chillers by:

-

Keeping the temperature steady and accurate

-

Using less electricity in big buildings and cooling jobs

-

Giving many cooling options for different needs

-

Letting users adjust settings to save more money

-

Some brands, like Daikin and Trane, use screw compressors with high energy ratings. These compressors help factories use less electricity. The OUMAL air cooled chiller uses a semi-hermetic screw compressor. This type is known for being efficient and working well for a long time.

Smart Controls

Smart controls are important for making chillers work better. Many new chillers use PLC systems and touch screens. These controls let workers set and watch the chiller in real time. The system can change how it works based on cooling needs. This saves energy and keeps the temperature even.

The OUMAL air cooled screw chiller uses a Siemens PLC control system. It has a touch screen that is easy to use. This system lets workers make changes fast and react to factory needs. Smart controls also help keep the system safe. They watch for problems like too much pressure or overload. Workers can see warnings and fix problems before they get worse.

Note: Smart controls and energy systems work together to save energy. They help the chiller run only when needed. This lowers costs and makes the chiller more efficient.

Reducing Costs

Industrial chillers help factories spend less money in many ways. Air-cooled chillers do not need cooling towers or extra water. This means they use less water and need less care. Using eco-friendly refrigerants, like R-407C, is good for the earth. It also helps the chiller work well in hot weather.

Studies show water-cooled chillers use less power than air-cooled chillers. But air-cooled chillers save money because they do not need water treatment or towers. This makes them good for places with little water. The OUMAL air cooled screw chiller uses R-407C. This helps it work well and saves money on water.

Factories that buy variable speed drive air-cooled screw chillers often get their money back in about 22 months. This means energy and care savings pay for the chiller in less than two years. Many factories pick air-cooled chillers to help the planet. These chillers use less material and lower-GWP refrigerants. This helps cut down on carbon emissions.

Tip: Picking the right chiller with smart controls and good compressors helps factories save money, use less energy, and protect the environment.

Maintenance and Reliability

Easy Maintenance

Air cooled screw chillers last a long time in factories. They have fewer moving parts than other chillers. This means they do not break as often. The design lets workers reach important parts easily. Technicians can check and fix things fast. Many factories pick screw chillers for strong cooling and easy care. Screw chillers need fewer repairs than reciprocating chillers. They also cost less to keep working over time. Cleaning the condenser coils and checking oil levels is important. This helps the chiller work well. If something breaks, modular maintenance keeps the chiller running. One part can be fixed while the rest still works. This stops long shutdowns and keeps the factory working.

|

Aspect |

Air-Cooled Screw Chillers |

Reciprocating Chillers |

Scroll Chillers |

Centrifugal Chillers |

|---|---|---|---|---|

|

Moving Parts |

Fewer |

More |

Fewer |

Single Compressor |

|

Maintenance Complexity |

Easier Access |

Higher |

Sealed Design |

Full Shutdown |

|

Maintenance Costs |

Lower Long-Term |

Higher |

Lower |

Higher |

|

Operational Impact |

Modular Maintenance |

N/A |

N/A |

Full Downtime |

Safety Protections

Modern air cooled screw chillers have many safety features. These features help stop damage and keep the chiller safe. Some main safety features are:

-

High and low pressure protection

-

Compressor overheating protection

-

Overloading protection

-

Flow switch to check water flow

-

Phase sequence and phase-missing protection

-

Exhaust overheating protection

-

Anti-freezing protection

-

Oil separator for proper lubrication

-

Refrigerant safety valve

-

Buzzer alarms for faults

-

Power phase failure protection

-

Coil over-heat protection

-

Temperature auto-switch

-

Refrigerant shortage protection

All these features work together to stop problems early. They also make it easier for workers to fix issues.

Warranty and Support

OUMAL gives a 15-month warranty for its air cooled screw chillers. This is longer than the usual 12 months from other brands. The company has good after-sales support. Customers can get help from trained service teams. They can order spare parts and ask for technical help. OUMAL also lets customers use remote monitoring and gives advice on care. These services help the chiller work well and make customers feel safe.

System Compatibility

Air cooled screw chillers can work with many air conditioning systems in factories. They connect to both new and old systems. Engineers plan how to keep air moving and not stop work. They follow the maker’s guide to fit the chiller with the system. Testing and checking make sure everything works together well. Many factories use these chillers to make their cooling better without big changes. Cleaning filters and looking for leaks helps the system run well.

Tip: Good planning and setup help stop problems when adding chillers to old systems.

Environmental Adaptability

Factories use air conditioning in many places. Air cooled screw chillers can handle hot, cold, or tough spots. They have strong fans and special covers to stop heat and rust. Some chillers work in heat up to 60°C. They use drives that change fan and compressor speed. This saves energy and keeps the temperature steady. The table below shows how these chillers work in different places:

|

Adaptation Feature |

Description |

|---|---|

|

Variable Frequency Drives |

Change speed for different loads and weather |

|

Heavy-duty Design |

Works in high heat, up to 60°C |

|

Corrosion-resistant Heat Exchangers |

Lasts longer in tough or chemical places |

|

Modular Design |

Fits in small spaces and is easy to add more |

|

Installation Clearances |

Needs space for air and repairs |

|

Environmental Protection |

Protects from bad weather and harsh stuff |

These features help air conditioning systems in factories work well anywhere.

Customization Options

Each factory needs something different for its air conditioning. Air cooled screw chillers can be changed in many ways. Companies pick the size, cooling power, and temperature they need. Some chillers have special parts to stay safe in risky places. Others cool things to very low temperatures for food or chemicals. Digital controllers help keep the temperature just right. OUMAL lets you use outside water tanks for more choices. Their team helps design chillers for special needs, space, and rules. This makes sure the cooling system fits and works well with air conditioning in factories.