Driven by China's "dual carbon" strategy and the push for green industrial transformation, the "2025 Conference on Technological Innovation and Application in Water Treatment for Key Industrial Sectors" was held in Zhangzhou, Fujian, from March 20-22, 2025.

Driven by China's "dual carbon" strategy and the push for green industrial transformation, the "2025 Conference on Technological Innovation and Application in Water Treatment for Key Industrial Sectors" was held in Zhangzhou, Fujian, from March 20-22, 2025.

Decoding New Trends in Industrial Water Treatment

This conference, a leading event focused on green and intelligent innovation in water treatment, was jointly organized by authoritative institutions including the Industrial Water Treatment Committee of the Chemical Industry and Engineering Society of China. Centered around "Empowering New Quality Productive Forces," it addressed challenges in water conservation, pollution reduction, energy efficiency, and performance enhancement in sectors like steel, petrochemicals, and new energy.

With three specialized seminars and over 30 technical reports, the conference presented a comprehensive matrix of solutions, spanning traditional industrial upgrades and emerging sector breakthroughs. It attracted numerous experts and scholars from universities, research institutes, and industrial enterprises.

From Individual Breakthroughs to Systemic Empowerment

Shanghai KSB Pump Co., Ltd., a model joint venture between KSB Group and Shanghai Electric Group, and KSB's core intelligent manufacturing base in China, has been deeply rooted in the Chinese market for nearly three decades. Combining German precision engineering with localized innovation, KSB Shanghai has become a leader in China's pump industry. Its products and services are widely used in general industry, power generation, petrochemicals, municipal water, building services, and wastewater treatment.

KSB not only manufactures high-quality pumps but also provides intelligent solutions covering the entire water treatment process. Ms. Cai Ying, Business Development Manager at KSB Shanghai, delivered a keynote speech titled "Efficient and Reliable Application of Pumps in Industrial Water Treatment under the Dual Carbon Context" at the 2025 Water Treatment Technology Seminar for the Energy and Chemical Industry on the afternoon of March 21.

KSB: Intelligent Manufacturing for Superior Water Systems

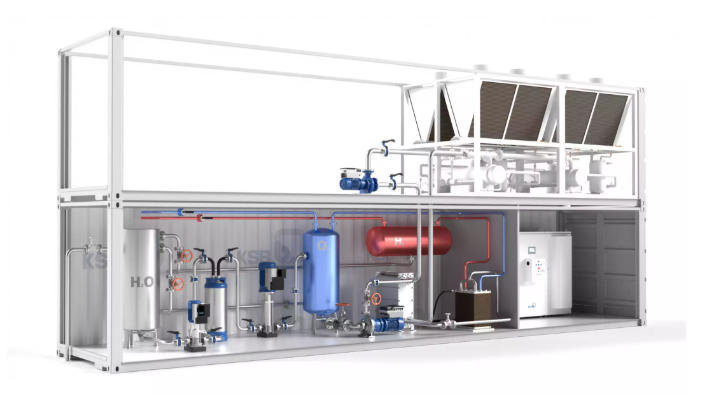

In her presentation, Ms. Cai, a seasoned expert in water treatment for general industry, showcased KSB's tailored, high-efficiency pump configurations for industrial water treatment systems. From raw water intake and pre-treatment to advanced treatment and wastewater reuse, KSB pumps, with their superior performance, intelligent control, and lean management, ensure efficient water conveyance, recycling, and compliant discharge. This helps industrial enterprises build green, low-carbon, and sustainable water cycles.

Cutting-Edge Technology Leads Green and Intelligent Innovation

Ms. Cai emphasized that pumps, as the "heart" of industrial water treatment systems, directly impact the system's efficiency, energy consumption, and stability. KSB Shanghai, through scientific selection, optimal configuration, and efficient operation and maintenance, creates pump solutions tailored to various industrial scenarios, ensuring the efficient and stable operation of the entire system across all stages.

In demanding applications like water treatment in the energy and chemical industries, wastewater treatment in the new energy sector, and ultrapure water production and wastewater treatment in the electronics industry, KSB's pump configurations significantly reduce energy consumption and enhance system reliability, providing robust support for green production.

Collaborating for a "Green" Future of Intelligent Manufacturing

KSB's presence in Zhangzhou showcased not only its outstanding products for industrial water treatment, such as MultiTec, Etanorm, and Movitec, and its advanced solutions, but also its deep insights into industry trends.

Driven by the "dual carbon" goals, industrial water treatment is rapidly evolving towards intelligence and sustainability. KSB will continue to leverage innovation as its engine, deepen its technological research and development, and provide industrial enterprises with more efficient and reliable water resource management support, collaborating with industry partners to create a new blueprint for green intelligent manufacturing.