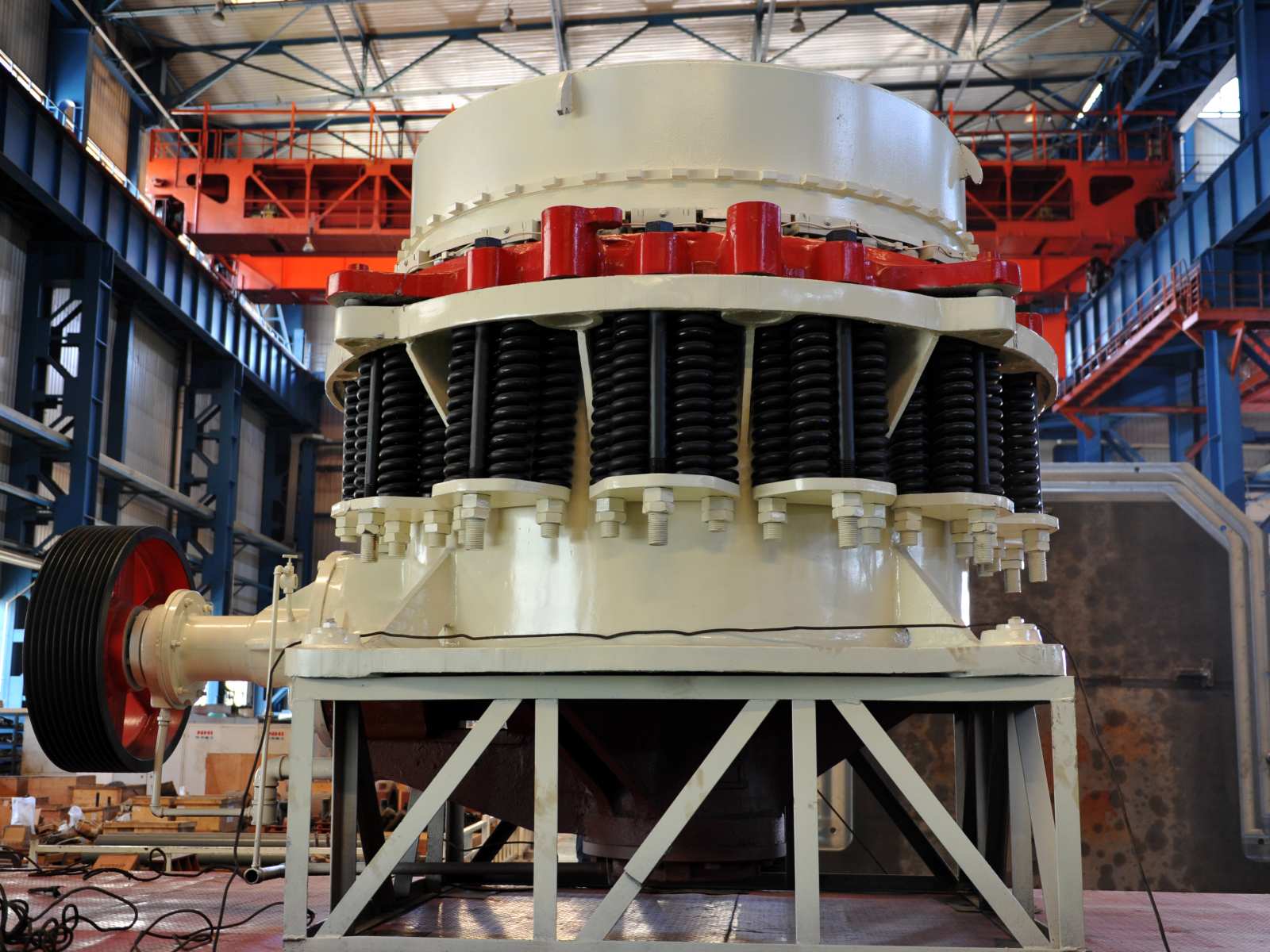

A cone crusher is a vital piece of rock crushing equipment that breaks rocks into smaller pieces. This machine is widely used in mining, recycling, and the production of building materials. NHI specializes in building durable cone crushers designed for heavy-duty applications.

- The market for cone crushers is projected to reach approximately USD 1.84 billion by 2024.

- Compression crushing, a technique employed by cone crushers, utilizes steel to press and break materials.

| Component | Function |

|---|---|

| Eccentric Shaft | Rotates the crusher head to effectively crush rocks. |

| Crusher Head | Breaks stones within the crushing chamber. |

| Conical Body | Applies pressure and friction to hold and crush stones. |

Cone Crusher Operation

Working Principle

You use a cone crusher to crush big rocks. The rocks get squeezed between two hard surfaces. The machine uses compression to make rocks smaller. The main parts are a moving mantle and a fixed concave. You put rocks in at the top. Gravity pulls the rocks down into the crushing chamber. The mantle moves in a circle and presses rocks against the concave. This crushes the rocks into smaller pieces. The space between the mantle and concave decides the size of the final product. If you make the gap smaller, you get finer material. If the gap is bigger, you get larger pieces.

Tip: Always check the gap before you start the crusher. The gap controls how big or small the crushed rocks will be.

Crushing Process

You can follow easy steps to see how material moves through a cone crusher:

| Step | Description |

|---|---|

| 1 | Material goes in through the feed hopper at the top. |

| 2 | Gravity pulls the rocks into the crushing chamber. The rocks get squeezed between the mantle and concave. |

| 3 | As rocks move toward the end, they get smaller from crushing. |

| 4 | Crushed rocks come out through the opening at the bottom shell. |

The gap setting is important in the crushing process. You can see how different gap sizes change the final product:

| Gap Setting Type | Resulting Particle Size |

|---|---|

| Finer Closed-Side Setting | More fine pieces |

| Coarser Setting | Bigger product sizes |

- Smaller gaps make more fine pieces.

- Bigger gaps give you larger pieces.

- The shape of the crushing chamber also changes the final size.

Setting the gap on a cone crusher is important for getting the size you want. You control the quality and consistency by changing this setting.

You might wonder how much material a cone crusher can crush. Throughput rates are different for each model:

| Crusher Model | Throughput Rate (tons per hour) |

|---|---|

| HPT Multi-cylinder Hydraulic Cone | 45 - 1200 |

| S Spring Cone | 27 - 1400 |

| HST Single Cylinder Hydraulic Cone | 27 - 2185 |

Safety matters when you use a cone crusher. You should always follow these safety steps:

| Safety Mechanism | Description |

|---|---|

| Safety Procedures | Follow all safety rules in the manual. |

| Personal Protective Equipment (PPE) | Wear hard hats, safety glasses, steel-toed boots, and bright clothing. |

| Lockout/Tagout Procedures | Use lockout/tagout steps when fixing or maintaining the machine. |

| Guarding and Safety Devices | Make sure guards, safety devices, and emergency stop switches work. |

| Safe Operating Procedures | Use the crusher the way the manufacturer and safety rules say. |

| Emergency Preparedness | Keep emergency shut-off switches and fire equipment easy to reach. |

NHI makes cone crushers with good safety features and strong throughput rates. You can trust their machines for tough jobs.

Components and Technology

Main Parts

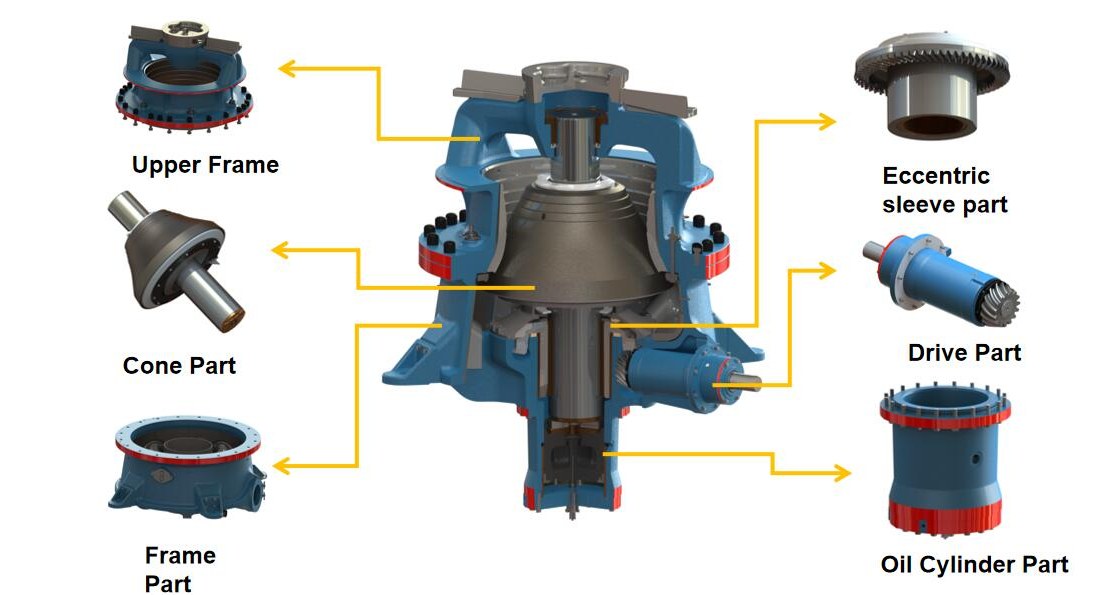

A cone crusher has many important parts. Each part helps break rocks into smaller pieces.

- Mantle: This part pushes rocks against the concave to crush them.

- Concave: It is a curved surface that works with the mantle to make the crushing space.

- Eccentric: The motor moves this part, so the mantle spins in a circle.

- Crushing Chamber: This is the area between the mantle and concave where rocks get crushed.

The crushing starts when you put rocks in at the top. The mantle turns and presses rocks against the concave. The rocks break into small pieces and fall out the bottom.

Efficiency Features

Modern cone crushers have smart features to help you work better and safer. Hydraulic systems let you change the gap fast. You spend less time fixing the machine and more time working. These systems also help clear the chamber if there is a problem. Automation checks the feed rate and size of the rocks. It changes settings to stop overload and keep the crusher working well. Predictive maintenance helps you find problems early and avoid breakdowns. Some cone crushers use roller bearings or bronze bushings. The design you pick changes how often you need to fix the machine.

NHI gives you cone crushers with advanced hydraulic and automation features. Their designs are easy to take care of and work well.

| Advantage | Description |

|---|---|

| Increased uptime | You can adjust settings quickly, so you lose less time. |

| Improved safety | The chamber can be cleared safely if the power goes out or stops suddenly. |

| Enhanced efficiency | You control the opening for steady product size and more output. |

| Durability | The machine lasts longer and does not break easily. |

| Ease of maintenance | There are fewer parts to replace or fix. |

Modern Innovations

There are many new ideas in cone crusher design. Companies like NHI and Metso add features to help you work faster and save money. Multi-action technology uses both piston and bowl movement. This means more uptime and lower costs. Under-load adjustment lets you change settings while the crusher is running. Energy-saving designs remove old drive parts, making the machine stronger and easier to use. Automation now gives real-time checks and helps you fix problems before they get worse. You can add new systems to old crushers. High-capacity and mobile cone crushers let you crush more rocks in less time.

| Innovation | Description |

|---|---|

| Multi-Action Technology | Uses piston and bowl movement for more uptime and lower costs. |

| Under-Load Adjustment | Lets you change settings and wear parts while working. |

| Energy Efficient Design | Makes the drive system simple and strong. |

| Real-time Monitoring | Watches performance and stops overload by itself. |

Types, Applications, and Maintenance

Cone Crusher Types

There are different types of cone crushers. Each type is good for certain jobs. The standard cone crusher has a short belt in the chamber. It makes bigger pieces and gives high output. The short head cone crusher has a longer belt. It makes smaller pieces after the first crushing. Mobile cone crushers can move to new places. You use them for crushing and recycling at different sites.

| Feature | Standard Cone Crusher | Short Head Cone Crusher |

|---|---|---|

| Shape of Crushing Chamber | Shortest parallel belt | Longest parallel belt |

| Particle Size of Crushed Products | Coarse particle size, high output | Fine materials, used after intermediate crushing |

| Width of Discharge Port | Wider discharge port, larger processing capacity | Narrower discharge port, smaller processing capacity |

Applications

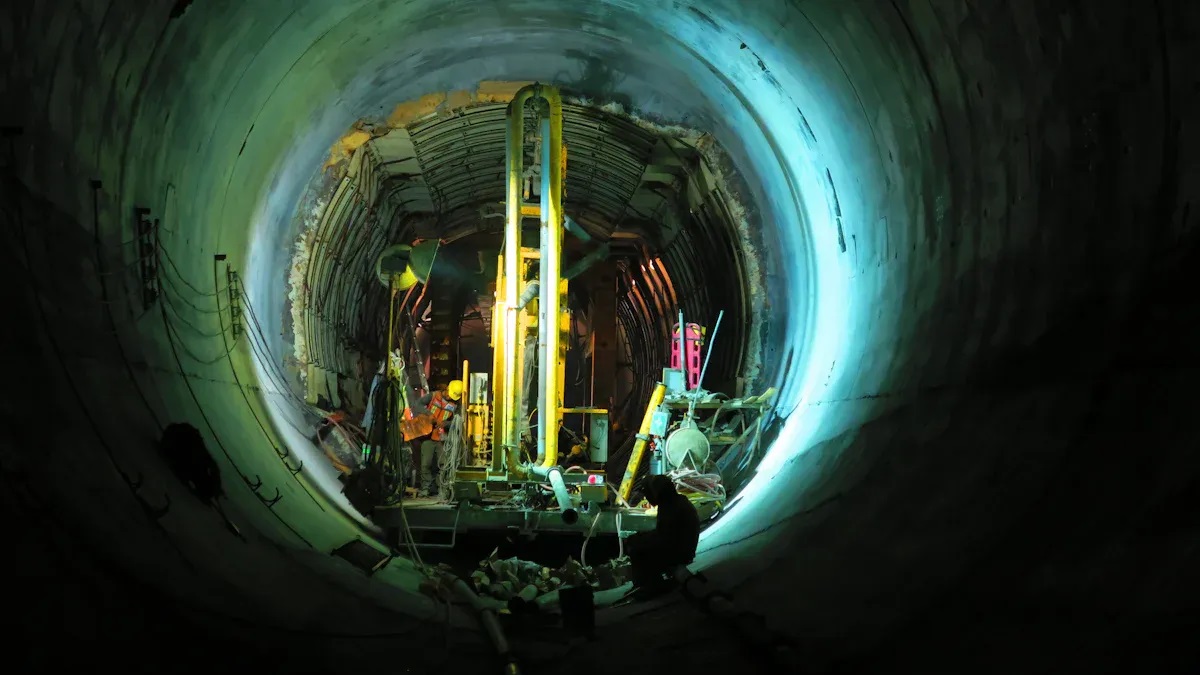

Cone crushers are used in many industries. They crush hard rocks and ores in mining. You use them to make good aggregates for roads and buildings. These machines recycle old concrete and bricks. They turn waste into new building materials. Cone crushers are also used in cement and ceramics factories. They help make materials smaller after the first crushing.

- Mining: Crush hard rocks, ores, and minerals.

- Aggregate Production: Make high-quality aggregates for construction.

- Construction and Demolition Waste Recycling: Turn waste into reusable materials.

- Quarrying: Break large rocks for building projects.

- Industrial Applications: Used in cement and ceramics production.

- Secondary and Tertiary Crushing: Reduce material size after primary crushing.

Tip: Mobile cone crushers let you recycle waste at the site. This saves you time and money.

Maintenance Tips

You must keep your cone crusher working well. Doing regular checks stops breakdowns and big repairs. Check oil levels and quality every day. Look at liners and parts for damage. Clean dust and dirt from important areas. Listen for odd sounds or shaking. Make sure bolts are tight and belts are not worn. Check the electrical system for problems. Keep safety devices working right.

| Maintenance Practice | Description |

|---|---|

| Follow manufacturer-recommended maintenance schedules | Stick to the guidelines for best results. |

| Conduct regular inspections and preventive maintenance checks | Find problems early and fix them. |

| Keep detailed records of servicing, repairs, and component replacements | Track history for future planning. |

| Use high-quality spare parts and lubricants | Good parts last longer and work better. |

| Train operators and maintenance personnel | Proper training keeps the machine running safely. |

Check important parts every day, week, and month. Daily checks include oil, temperature, and vibration. Weekly checks look at hydraulic parts and bearings. Monthly checks cover inside parts and belts.

Note: Most downtime happens from hot oil, low oil pressure, and too much shaking. Regular checks help you stop these problems.

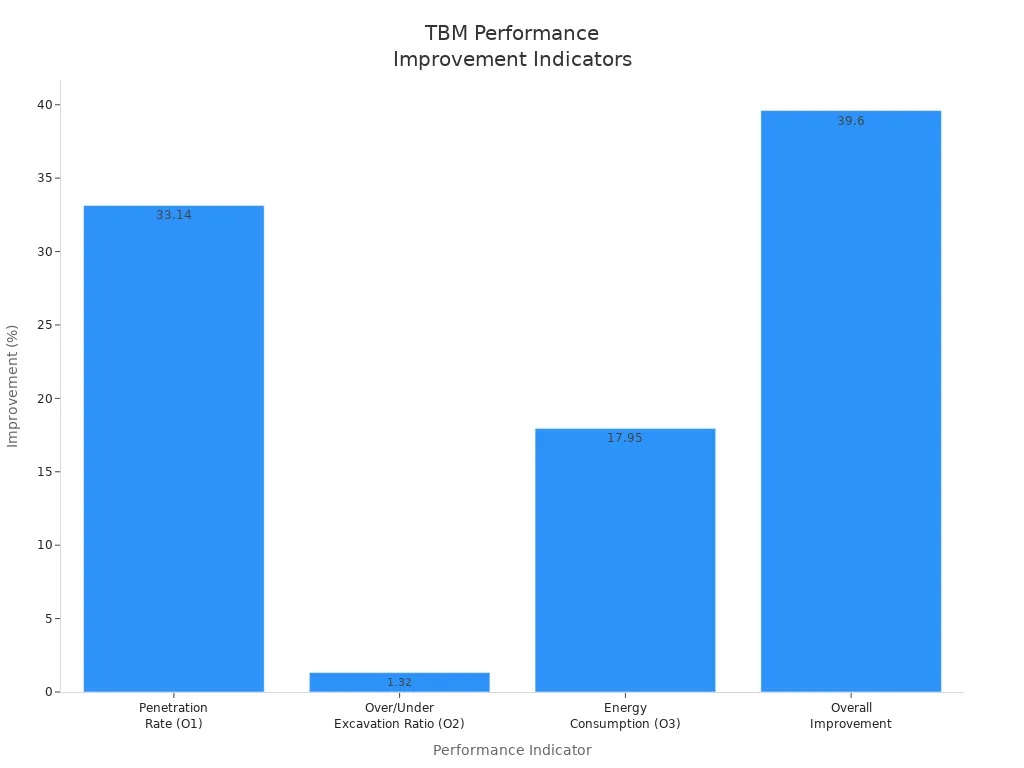

Cone crushers crush rocks fast and help you save money. You get good quality rocks and less time fixing the machine. You also use less energy.

- The best models can work for more than 20 years.

- Smart automation means you need fewer workers and do fewer repairs.

- The market is growing at 5.7% each year. It will reach $5,378.5 million by 2034.

| Innovation Type | Benefit |

|---|---|

| AI Optimization | Uses less energy and makes better-sized rocks |

| Predictive Maintenance | Machine works longer and breaks down less |

NHI keeps making new designs so the machines work better and are easier to use.